Reflectance Spectroscopy

In a fraction of a second, the photovoltaic (PV) reflectometer measures the reflectance spectrum of a wafer or cell that is dimensionally within 6 in. × 6 in.

The measured reflectance plots are deconvolved to derive physical parameters, including surface roughness and texture, antireflective coating thickness, metallization area and height, and backside metallization properties.

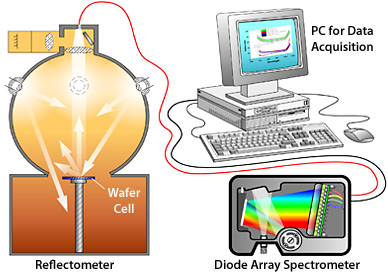

The reflectance measurement uses a principle of reciprocity

A schematic of the reflectometer

Reflectometer results on three groups of commercial PV-Si wafers (4.5 in. × 4.5 in.)

at different stages of solar cell processing.

antireflective (AR) coating thickness: 794 to 858 Å

Reflectance curves (in arbitrary units) of 5-in. × 5-in. wafers taken with the PV-Reflectometer.

These data yield information on the surface roughness, texture height, and oxide and

AR coating thicknesses.

AR coating thickness: ˜600 Å

Share

Last Updated April 3, 2025